- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

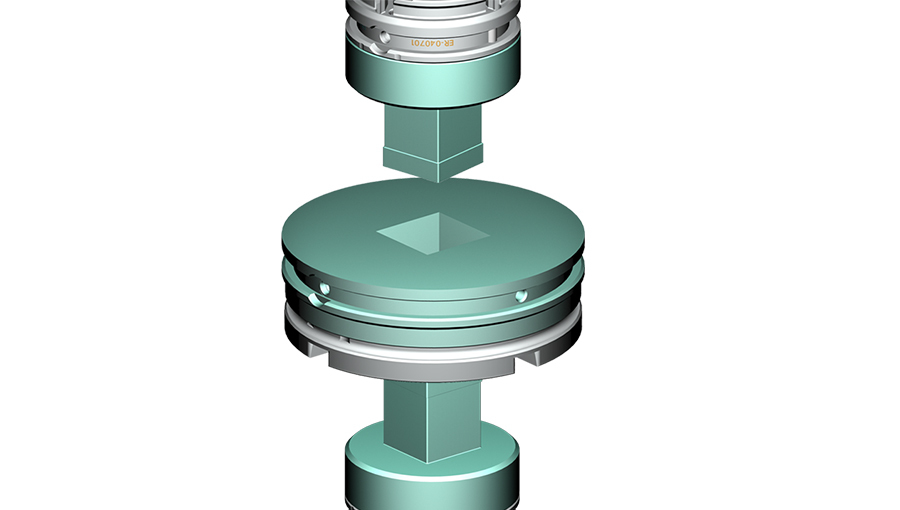

EROWA PM Tooling System

The rapid-change tooling system for powder presses

As a consequence of variable part forms and different part sizes, powder press adapters must be reset flexibly and quickly. A rapid-change tooling system makes a crucial contribution to a distinct reduction in resetting times.

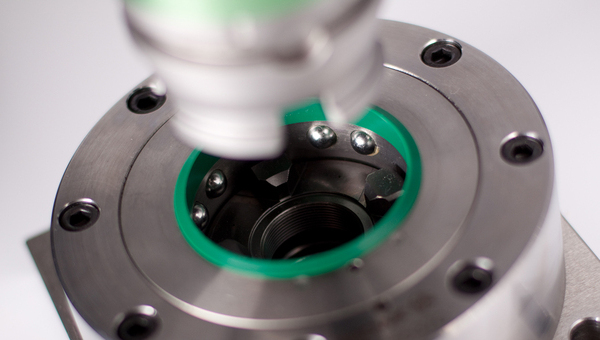

EROWA’s PM Tooling System constitutes the precise interface between punch, die plate and powder press.

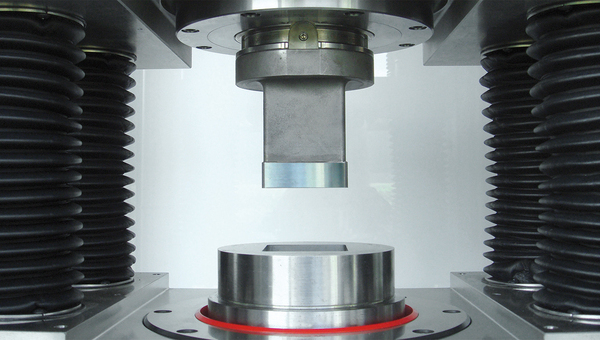

Systematic clamping

The PM Tooling chucks are directly integrated into the powder press or into the press adapter and constitute the precise and universal basis for the press tools.

Quick change of press tools

Consequently, press tools such as punches and die plates can be clamped and exchanged quickly and with precision.

The 4x90° pallets are divisible; repeatability is <0.002 mm.

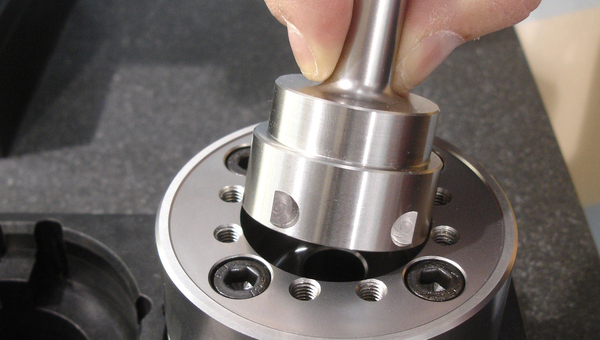

Retrofitting existing equipment

Punches and die plates that are already in use can be adapted to PM Tooling pallets and aligned with precision. After this, they can be used throughout the system.

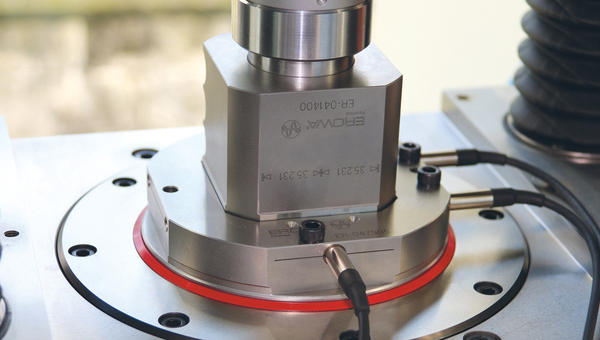

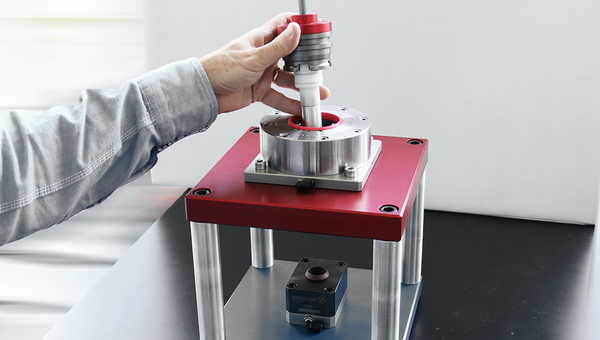

Aligning punches

With the EROWA PM Tooling aligning system, bottom and top punch chucks can be aligned with precision on the powder press.

Sensors or gauges serve to align the chuck positions according to requirements.

Different system sizes

Different PM Tooling system sizes can be adapted together in order to manufacture small and big parts on one and the same powder press. Thus resetting on the press becomes even more economical.

EROWA’s PM Tooling System is extremely flexible and provides various adaptation options for refined combinations of different system sizes.

PM Tooling center pin chuck

The positioning and clamping of center pins on powder presses is substantially simplified by the use of the EROWA CPC center pin tooling system.

Center pins can be clamped in the fixed or swimming position according to requirements. Palletized center pins and the correspondingly prepared bottom punch are preassembled outside the press and placed and clamped in the planned positions as units.