- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

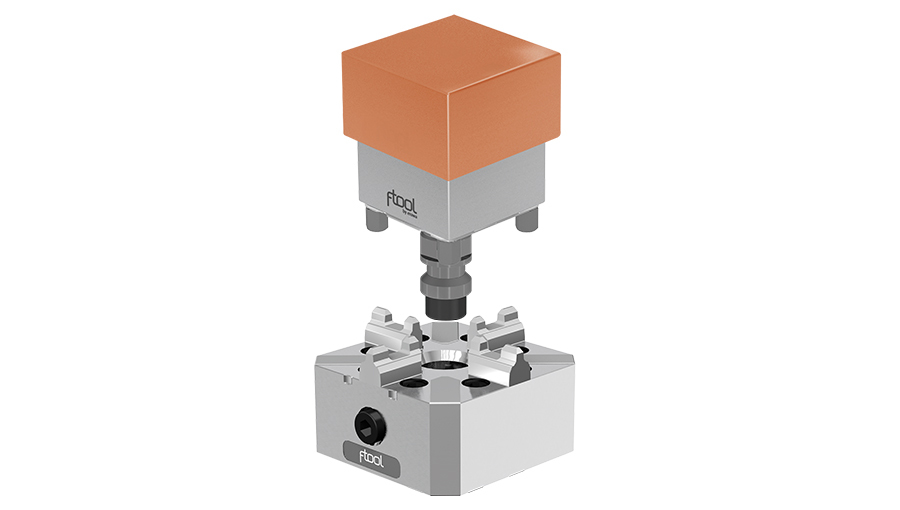

F-Tool (by EROWA)

Simple, precise, good value

F-Tool is the product line in EROWA's portfolio for manual workpiece clamping operations. The products are aimed at cost-conscious newcomers to workpiece palletization and have been optimized for use in EDM and WEDM.

Clamping workpieces flexibly and with precision, machining them in a stable position, setting them up without any hitches: these are the outstanding advantages of the F-Tool (by EROWA) products.

For further information about the F-Tool (by EROWA) product range please visit our website www.f-tool.com.

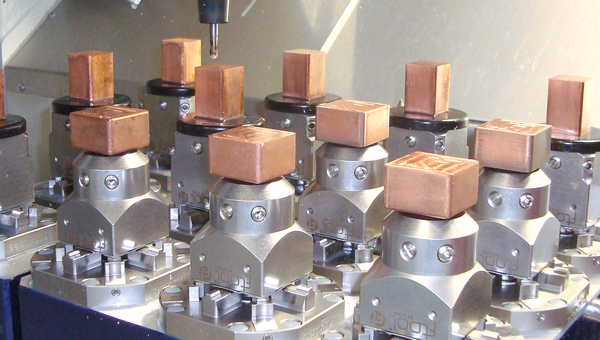

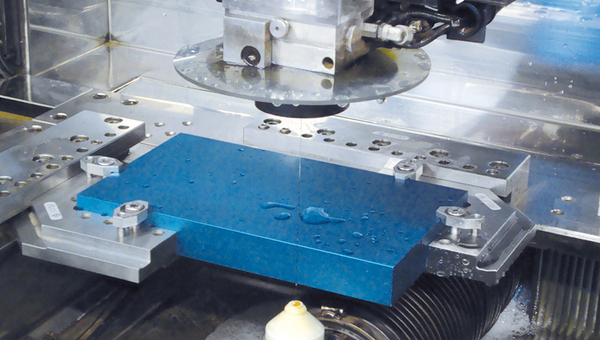

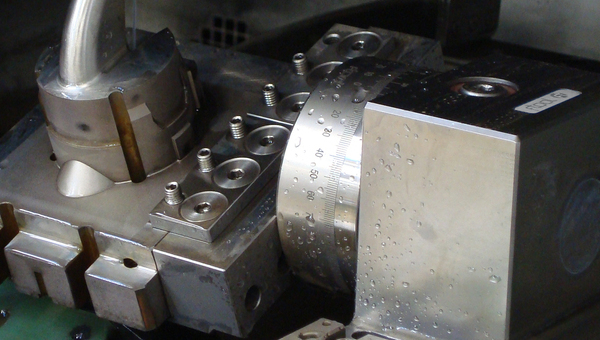

F-Tool products used in EDM

Many advantages

Flexible and precise clamping, stable machining, simple set-up: these are the most conspicuous advantages of the F-Tool (by EROWA) products used in EDM.

Varied range

The varied F-Tool electrode holders are ideally suitable for the production of electrodes, for milling, turning, grinding and EDM

Simple to fit

The F-Tool chucks are operated manually. Without any compressed air supply, installation on machine tables and fixtures is extremely simple.

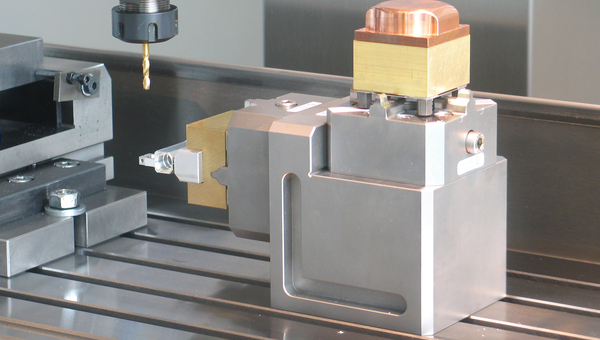

Precise and high clamping power

The manual chuck 150P is characterized by its robust and precise design and has a high degree of clamping power.

Repeatability for workpiece carriers is 0.002mm. The chuck is also ideally suitable for use on grinding spindles and dividing heads.

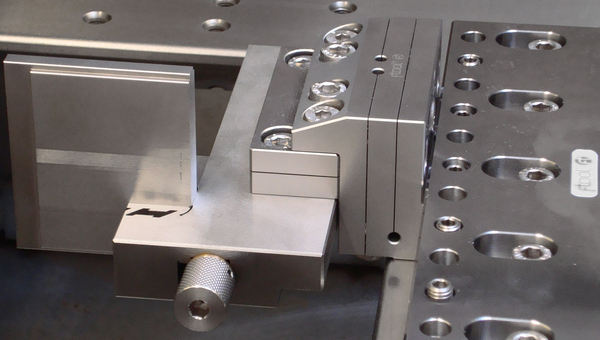

Practical clamping solutions

Depending on the size of the workpiece, it can be attached with F-Tool clamping blocks according to requirements.

The clamping blocks are suitable for use on F-Tool clamping rails, T-slot pallets and hole grid plates.

Universally operational

From milling to EDM - F-Tool electrode holders can be universally used in all operations.

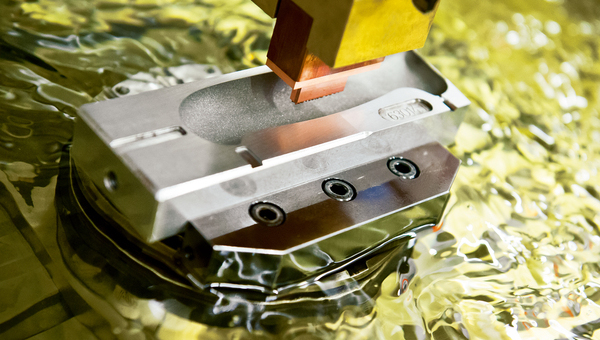

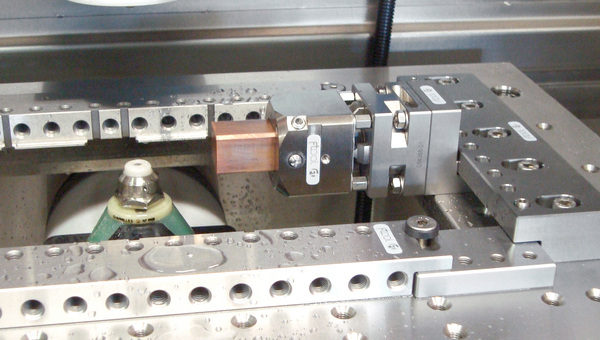

F-Tool products used in WEDM

Modular clamping system

With well-thought-out combinations of vises, clamping elements and clamping beams, any conceivable workpieces can be clamped according to specifications.

F-Tool (by EROWA) products offer a great number of advantages.

Flexible basis

After milling, the workpiece can be clamped onto the WEDM center for further machining in a few quick steps.

The Chuck 50 is the universal basis for workpiece carriers on WEDM /EDM centers, as well as for milling and grinding operations.

Practical starter kit

A range of varied and requirements-based starter kits provide a favorably priced possibility of clamping workpieces to WEDM centers in a flexible manner.

For small workpieces

With mini-brackets, small parts can also be reliably clamped for machining operations.

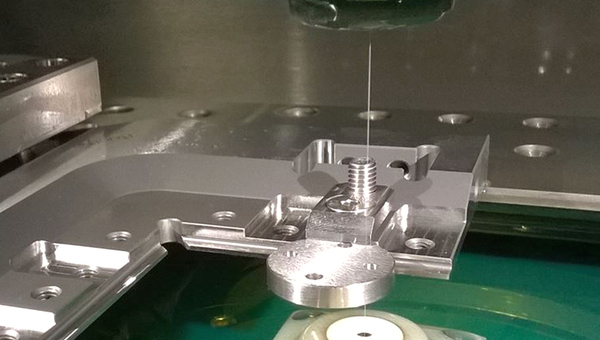

Adjustable in three dimensions

The pendulum head can be adjusted quickly, with precision and in three dimensions.

Besides many F-Tool clamping elements, it is compatible with EROWA tooling systems. It can be preset and aligned on a measuring station outside the machine and is clamped on the F-Tool base rail of the machine table.

For special angles

Angle indexation table with 90° grid indexation or continuous indexation.

Suitable for direct use on WEDM machine tables with 50mm hole grids or on F-Tool base rails.