- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

EROWA Wire EDM Tooling System

The modular tooling system for WEDM

The EROWA Wire EDM tooling system frees up your valuable WEDM machines from unproductive setting-up and preparation times.

The well-thought-out combination of vises, clamping elements and clamping beams enables you to clamp all conceivable workpieces in an appropriate manner.

The repeatability of the Wire EDM tooling system allows for presetting outside the machine and for safe automatic loading operations.

The right equipment for every application

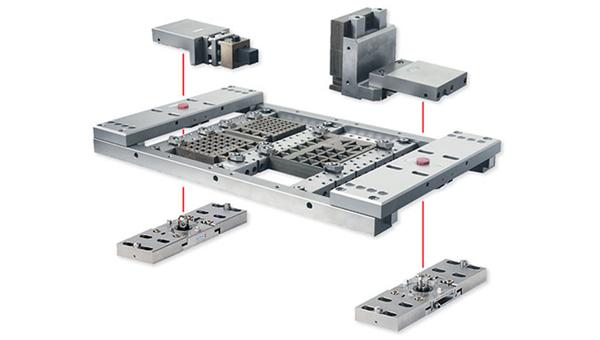

The EROWA flat chucks on the machine table constitute the flexible interface with the workpiece carriers.

The EROWA Wire EDM tooling system is suitable for single palletization or multiple palletization in a clamping frame.

Everything fits

There are suitable and flexible clamping elements for every size and type of workpiece.

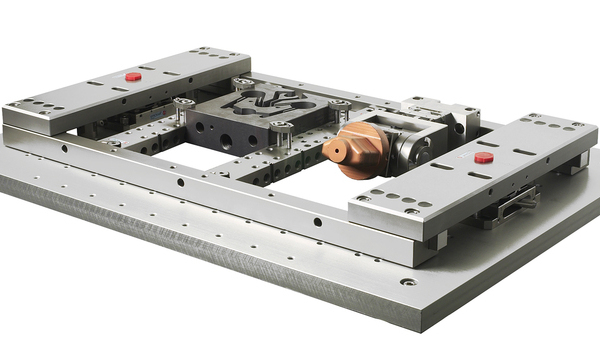

The workpiece to be machined is attached to the clamping elements with brackets.

Special workpiece mount

The Prisma clamping element for cylindrical parts: fitted to the pendulum holder, the workpiece can then be adjusted in three axes.

Clamping frames for different workpieces

Multiple palletization in a clamping frame: the workpieces to be machined are fitted to the clamping beams, which are individually arranged in the clamping frame.

In this way, workpieces of different dimensions are positioned in the same clamping frame, and various jobs can be completed in the same clamping frame.

The machine remains productive

While the next job is prepared, the machine remains productive. The set-up work is carried out in optimal surroundings and without any time pressure.

Throughput times are substantially reduced since no set-up work is done on the machine.

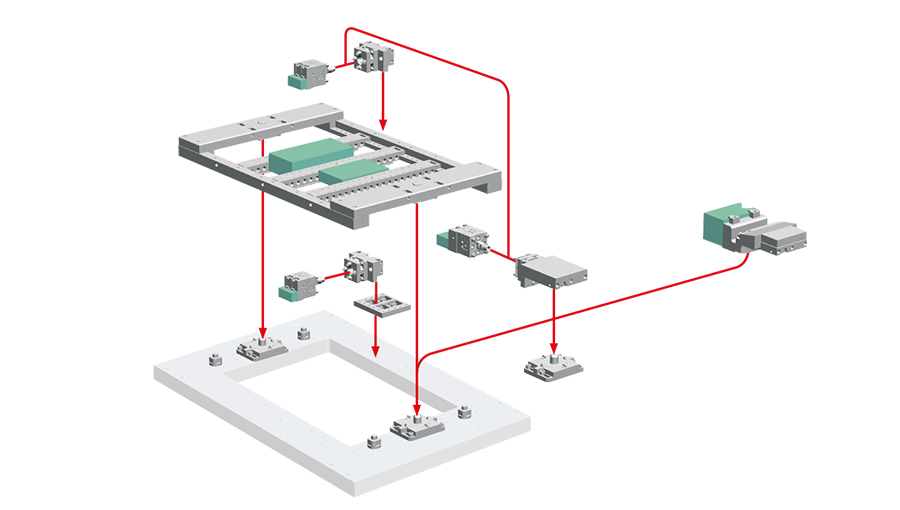

Automation

Since WEDM machines are loaded automatically, the share of productive hours is substantially increased.

An EROWA robot places the workpiece carrier on the machine with speed and precision.

We would like to advise you about an appropriate automation solution.