- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

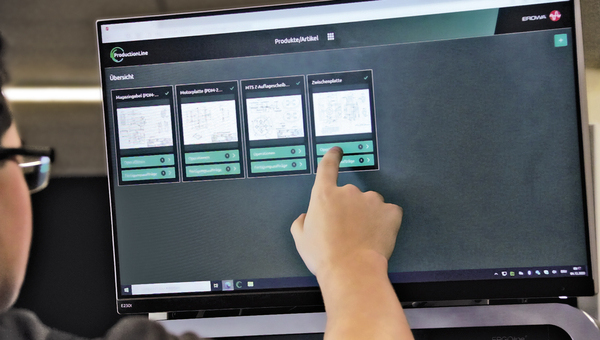

Software package EROWA JMS 4.0 ProductionLine – data automation – no robot

Starting digital production the easy way

With the EROWA JMS 4.0 ProductionLine starter software package, we enable you to start digital production the easy way, even for machines that are loaded without a robot.

Optimize the data flow in your machining processes in chip-cutting production.

The JMS 4.0 ProductionLine process control system controls and monitors your machine. The complete all-round compatibility of the data allows for comprehensive checks and process security.

The complete software package with all you need

Use the convincing advantages of data automation.

The EROWA JMS 4.0 ProductionLine starter software package contains selected software modules and hardware components.

Central order management

NC programs are allocated to orders / workpieces in advance.

JMS® 4.0 ProductionLine possesses a wide variety of interfaces with order and production planning systems such as ERP / CAD / CAM and others.

Fast and safe machine set-up

With the handheld reading device, the operator is able to "chip" fixtures and workpiece carriers, and load the programs on the machine easily, quickly and reliably.

User-friendly and easily manageable

|

All the data that are relevant to production are displayed in a user-friendly fashion. Updated status messages and signals support the operator in real time. The status of the production cell can be easily recognized even at a distance: colors provide clear signals of what is going on. |

Tool life monitoring

Besides the workpieces and the NC programs, the matching tools must also be ready. Whether this is the case and how long their tool life still is can also be read from the machine memory.

JMS 4.0 ProductionLine ensures an easy presentation of the tools on the machine, including state, tool life, tool breakage and the prospect of production time still available with the existing tools.

Transparency about productivity

Order or machine reports can be generated with only a few clicks.

The reporting application's user-friendly surface and availability throughout the network makes it an indispensable tool for process optimization.