- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

EROWA JMS 4.0 ProductionLine

The universal production process control system for chip-cutting machining operations.

Within the overall concept of Industry 4.0, EROWA’s JMS® 4.0 ProductionLine production process control system occupies an important position. It maps a large part of the functionalities which fall under the heading of “smart factory”.

This provides users of chip-cutting production with significant advantages: it is clear at all times which workpiece is engaged at which position in the process at what time.

The JMS® 4.0 ProductionLine production process control system links up all the data and controls the entire production process. Its software connects machines with the widest variety of manufacturing technologies without any problems.

Controlled data flow

The JMS® 4.0 ProductionLine process control system takes on the planning, controlling and monitoring functions of production plants.

The complete universality of the data allows for genuinely comprehensive control and process security.

The JMS® 4.0 ProductionLine system integrates machines with the widest variety of technologies without any problems. Its software is modular and can be extended according to requirements.

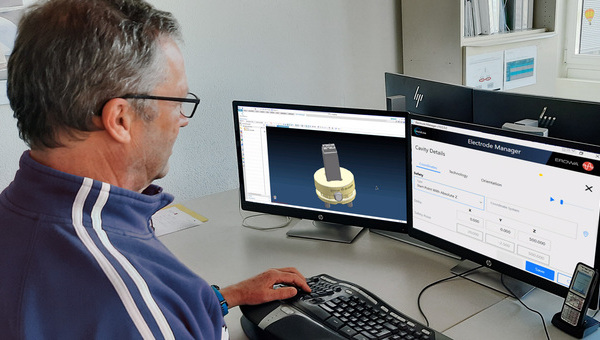

User-friendly and uncluttered

The JMS® 4.0 ProductionLine system provides clarity and transparency.

The order list, priorities, CNC programs, tool management and the current status messages provide the operator with the relevant facts at a glance.

Even from a distance, the status of the production facility can be discerned clearly. Color signals clearly display what is going on.

Simple data import/export

The JMS® 4.0 ProductionLine system is equipped with the widest variety of interfaces with order processing and production planning systems such as ERP, PPS, CAD, CAM, etc.

This means that direct imports, but also feedback, become substantially faster and more secure. And the current production status is recorded and displayed in real time.

Increased autonomy

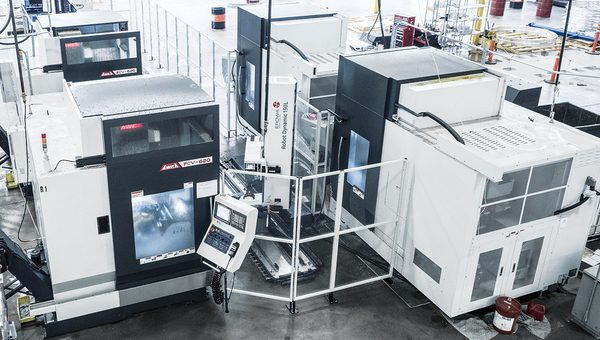

The automation of production processes with the help of an EROWA robot generates manufacturing hours that have not been exploited before. During the third shift and at weekends, production becomes autonomous.

This requires precise yet flexible planning. The JMS® 4.0 ProductionLine system is configured precisely to satisfy specifications and requirements and provides exact data for every production step.

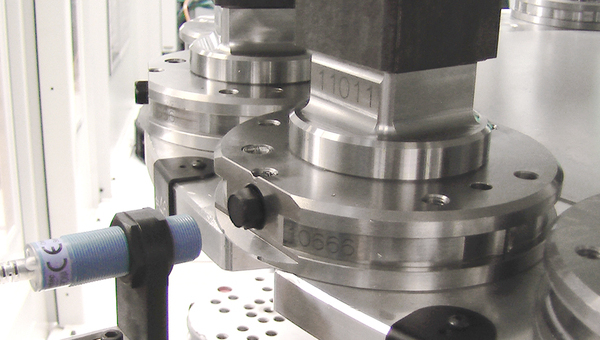

Universal identification

The JMS 4.0 ProductionLine system clearly states which workpiece occupies which position in the process at what time.

The pallets loaded with workpieces are unmistakably identified with a chip.

At every station in the production process, this unmistakable identification can be made by the EROWA EWIS™ system.

Tool life monitoring

Besides the workpieces and the NC programs, the appropriate tools must also be made available. Whether they are indeed ready and what life they still have can be read out of the machine’s own memory.

The JMS 4.0 ProductionLine control system provides a clear display of the tools on the machine, including status, tool life, tool breakage and a preview of the production time still available with the existing tools.

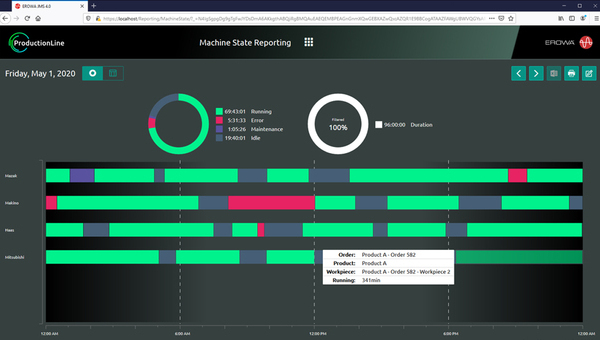

Reporting

With a few clicks and in a simple way, the historical machine time utilization can be displayed, as well as order reports.

Thanks to the latest web technology, the reporting application can be accessed from any workstation without additional installation.

Easy identification of the production time

The OEE (Overall Equipment Effectiveness) dashboard shows the efficiency status at a glance.

Different views provide a clear and structured overview for all production cells, or individually in detail for a single machine.

Maintenance contract

With the JMS 4.0 maintenance contract, you receive first-hand help when a malfunction occurs. Our experts are then available to you by telephone and remote maintenance free of charge.

Updates to the latest software version are available free of charge and new functions can be added easily.