- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

Preventive Maintenance – for equipment and systems

Best availability for your EROWA technology

Efficiency can only be achieved through planned production interruptions.

Preventive maintenance is cheaper than repairs. We are offering tailor-made „carefree packages“ for the EROWA components installed on your production line.

And best of all: Sign a maintenance contract right at the time of purchase and we will grant you an extended warranty.

You determine maintenance work

We recommend an annual inspection and maintenance of the chucks. The overhaul is carried out according to the maintenance schedule. All parts are washed and re-greased, all wear parts are replaced and the chuck is realigned on the machine

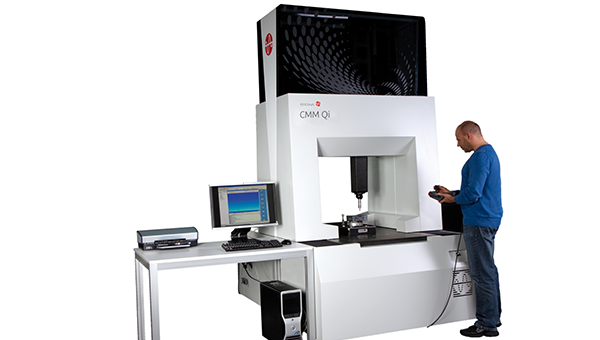

Annual check of components

Measuring equipment must be calibrated to achieve ISO standards. This is carried out by trained technicians. A certificate serves as proof of conformity.

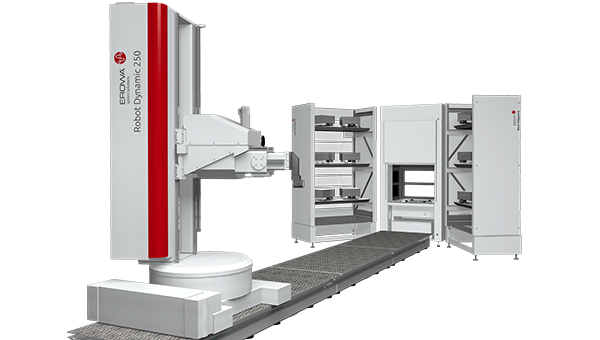

Availability of robots

We recommend an annual check of the basic functions. Defined wear parts are replaced with each maintenance. If necessary, the travelling paths are reprogrammed. Software updates are installed.

Software updates twice a year

Always kept up to date, software is safe and reliably operational. New service packs and updates are available. You have access to telephone and remote support at any time.

Preventive maintenance

Contact your nearest EROWA branch for a consultation on a tailor-made maintenance contract.

Prevention beats repairs