- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

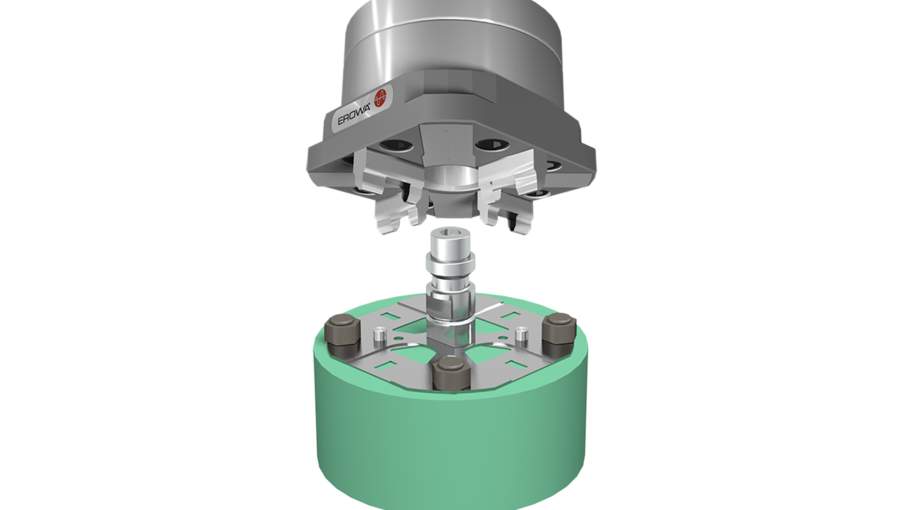

EROWA EDM Tooling System

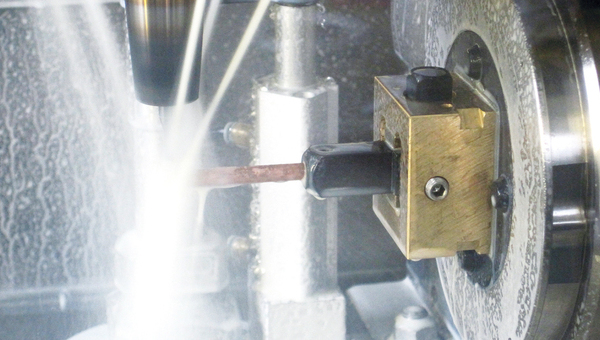

The tooling system for EDM and milling

Fast and precise resetting in tool-making and in light chip removal: save time and money by using the EROWA EDM Tooling System.

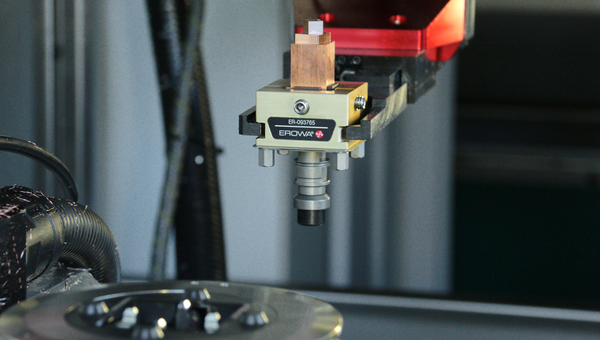

The basis of this workpiece clamping system is constituted by the EROWA ITS chucks, which can be fitted and aligned on the machine table or on the machine quill.

Workpiece and electrodes are fitted to and set up on system carriers such as pallets, electrode holders, centering plates, etc. – and production can start.

A suitable variant for every job

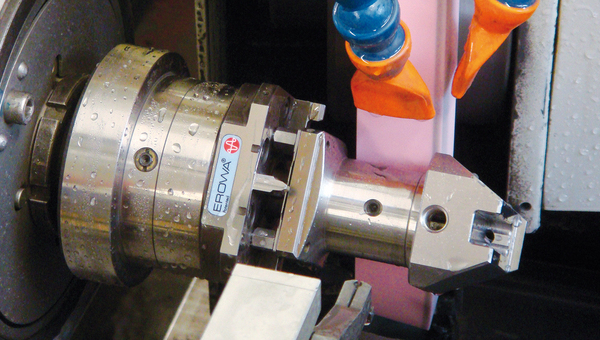

The applications of ITS chucks are as many-faceted as the challenges presented by jobs in precision mechanics and tool- and mold-making.

Depending on workpiece size, we offer a considerable range of different suitable chuck variants.

Quick resetting

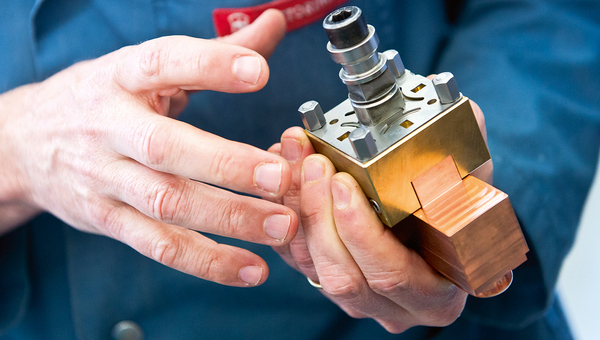

Fixed reference positions: the chucking spigot and the centering plate guarantee precise positioning in the chuck and powerful clamping of electrode holders.

The next job is prepared while the machine is productive. Then, there is a quick resetting operation, without loss of time through re-alignment and re-positioning of the electrode holder.

Universal interface

EROWA ITS chucks can be used universally on all machines.

Workpieces and electrodes pass through the entire production chain (turning, milling, grinding, EDM, WEDM, and measuring and presetting stations) palletized on the same system carrier.

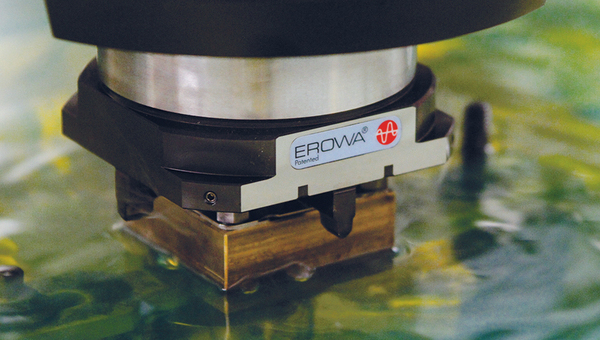

Precise

Precision and reliability in the machine tank and on the quill of the EDM machine.

Workpiece holders are divisible 4 x 90°.

The repeatability of 0.002mm guarantees universal and precise positioning.

Safe and sealed

The sealing plate of the EROWA ITS 50 Holder C and the sealing ring provide a form-fit seal.

This ensures that the chuck is optimally protected against contamination and the penetration of liquids.

Automation

Automatic loading by an EROWA robot provides the CNC machine with unforeseen autonomy. Marginal and night hours are used productively, and throughput times are reduced.

The entire EDM tooling system can be automated. A large selection of EROWA loading devices supplies an appropriate solution to every application.